The combination of functional modules allows for any air treatment process, from the simplest supply and exhaust of purified air to the preparation of supply air in the range:

|

application |

An air-conditioning and ventilation systems with standard purity requirements as preliminary filter An air-conditioning and ventilation systems with strict purity requirements as preliminary and secondary filter An air-conditioning and ventilation systems with standard or strict purity requirements as the final filtration stage Catching fat particles and heavy pollutants (metal filter) |

|||

|

type |

Metal plate filter G2 - ISO COARSE |

Plate filter: G4 - ISO COARSE M5 - ISOePM10-70% |

Minipleat filter: M5 - ISOePM10-70% F7 - ISOePM2,5-60% F9 - ISOePM1-80% |

Bag filter: M5 - ISOePM10-50% F7 - ISOePM2,5-65% F9 - ISOePM1-70%/80% |

|

metal filter |

Multi layer mesh covered on both sides with galvanized steel mesh mounted in 50mm thick frame Filteration mesh made of galvanized steel |

|

plate filter |

Filter textile covered on both sides with galvanized steel mesh Mounted in 50mm thick frame Filter textile made of synthetic polyester filaments |

| minipleat filter |

Mini pleat filter packages with hot melt separators Mounted in 50/100 mm thick frame Glass or synthetic fabric refill (100% polypropylene) |

|

bag filter |

Pockets sewn and placed on wire truss; bags lenght 300/500mm Mounted in 25mm thick frame; eccentric crimping Three-layer synthetic non-woven, polypropylene, using micro fibres |

|

metal filter |

Filtration grade Am: 80% End pressure drop Δp: 120Pa Maximum air velocity v: 4,2m/s Maximum working temperature: 300°C |

|

plate filter |

Filtration grade Am: 82% ÷ 92% End pressure drop: Δp: 150Pa ÷ 200Pa Maximum air velocity v: 4,2m/s Maximum working temperature: 90 ÷ 100°C |

| minipleat filter |

Filtration grade Am: 95% ÷ 99% Final pressure drop: Δp = 150Pa ÷ 200Pa Maximum air velocity v: 4,2m/s Maximum working temperature: 80°C |

|

bag filter |

Filtration grade Am: 95% ÷ 99% Final pressure drop: Δp = 200Pa ÷ 300Pa Maximum air velocity v: 3,7 ÷ 4,6m/s Maximum working temperature: 90 ÷ 100°C |

Application:

Exchanger medium connection:

(Conformance to standards: EN 308, EN 1216, EN 13053)

|

application |

An air-conditioning and ventilation systems with standard purity requirements as preliminary filter An air-conditioning and ventilation systems with strict purity requirements as preliminary and secondary filter An air-conditioning and ventilation systems with standard or strict purity requirements as the final filtration stage Catching fat particles and heavy pollutants (metal filter) |

|||

|

type |

Metal plate filter G2 - ISO COARSE |

Plate filter: G4 - ISO COARSE M5 - ISOePM10-70% |

Minipleat filter: M5 - ISOePM10-70% F7 - ISOePM2,5-60% F9 - ISOePM1-80% |

Bag filter: M5 - ISOePM10-50% F7 - ISOePM2,5-65% F9 - ISOePM1-70%/80% |

|

metal filter |

Multi layer mesh covered on both sides with galvanized steel mesh mounted in 50mm thick frame Filteration mesh made of galvanized steel |

|

plate filter |

Filter textile covered on both sides with galvanized steel mesh Mounted in 50mm thick frame Filter textile made of synthetic polyester filaments |

| minipleat filter |

Mini pleat filter packages with hot melt separators Mounted in 50/100 mm thick frame Glass or synthetic fabric refill (100% polypropylene) |

|

bag filter |

Pockets sewn and placed on wire truss; bags lenght 300/500mm Mounted in 25mm thick frame; eccentric crimping Three-layer synthetic non-woven, polypropylene, using micro fibres |

|

metal filter |

Filtration grade Am: 80% End pressure drop Δp: 120Pa Maximum air velocity v: 4,2m/s Maximum working temperature: 300°C |

|

plate filter |

Filtration grade Am: 82% ÷ 92% End pressure drop: Δp: 150Pa ÷ 200Pa Maximum air velocity v: 4,2m/s Maximum working temperature: 90 ÷ 100°C |

| minipleat filter |

Filtration grade Am: 95% ÷ 99% Final pressure drop: Δp = 150Pa ÷ 200Pa Maximum air velocity v: 4,2m/s Maximum working temperature: 80°C |

|

bag filter |

Filtration grade Am: 95% ÷ 99% Final pressure drop: Δp = 200Pa ÷ 300Pa Maximum air velocity v: 3,7 ÷ 4,6m/s Maximum working temperature: 90 ÷ 100°C |

(Conformance to standards: EN 308, EN 1216, EN 13053)

Exchanger medium connection

(Conformance to standards: EN 308, EN 1216, EN 13053)

Exchanger connection

Counterflow plate heat exchanger

(Conformance to standards: EN 308, EN 13053)

Counterflow plate heat exchanger

Application

Type

Max. permitted air velocity: v = 4,5m/s

Roof / Intake / Outtake

Door Locks and Handles

Inspection window

Internal lighting

|

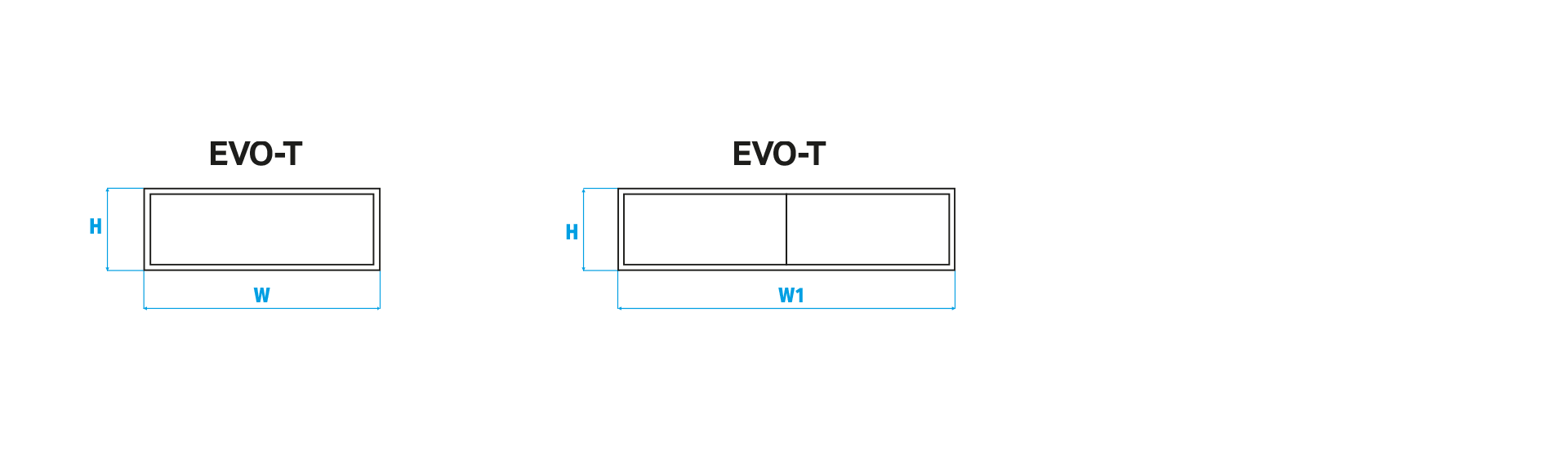

SIZE |

VMIN |

VOPT |

VMAKS |

EXTERNAL DIMENSIONS |

|||||

|

SUPPLY OR EXHAUST UNITS |

SUPPLY EXHAUST UNITS | ||||||||

|

W |

H |

HTOT |

W1 |

H1 |

H1TOT |

||||

|

4100 |

500 |

1500 |

2000 |

661 |

355 |

- |

1 322 |

- |

- |

|

1200 |

1000 |

2100 |

3500 |

961 |

355 |

- |

1 932 |

- |

- |

|

9200 |

1200 |

2900 |

5200 |

961 |

475 |

- |

1 932 |

- |

- |